When choosing the material for your outdoor kitchen, you have probably heard that stainless steel is the most durable and long-lasting option. As with most metals (stainless steel, aluminum, nickel, and manganese) exposed to the outdoor elements, there is always the concern for rusting and corrosion over time. Although stainless steel is a superior metal in the fact that it’s the best option for your outdoor kitchen cabinets due to corrosion resistance, it is not maintenance-free. It is stainless – not stainproof – meaning it must be properly and regularly cleaned to prevent rust and corrosion.

Brown Jordan Outdoor Kitchens manufactures cabinets using the most popular grades of stainless steel (304 and 316) for outdoor kitchens. All the different stainless steel grades are composed of iron alloys and the element chromium. At least 10.5% of the material must be chromium to be considered stainless steel, and this key element is the main fighter against rust.

See Related – 304 vs 316 Stainless Steel: What’s the Difference?

To reduce overall maintenance and prevent bare stainless steel from corrosion, adding a powder coat finish to your cabinets will add beauty and make your cabinets virtually maintenance-free. However, it is important to consider the ways in which bare stainless steel can be susceptible to rusting.

When Does Stainless Steel Rust?

If normal steel is exposed to oxygen, ferric oxide forms and creates the well-known rust color. The presence of chromium in stainless steel causes chromium oxide to form instead, and the chromium oxide layer makes stainless steel resistant to rust, slowing down the corrosion rate. Stainless steel that contains sufficient levels of chromium will continue to be protected from rust and corrosion. Under certain circumstances, though, stainless steel becomes vulnerable. These circumstances include contact with corrosive chemicals, the presence of normal steel on the stainless steel, or exposure to extremely high temperatures.[1]

Contact with corrosive chemicals without proper cleaning (use stainless steel cleaner) is sure to corrode stainless steel metal over time. For instance, exposure to seawater or pool water can cause stainless steel rusting due to the corrosive nature of chlorine in the saltwater and in pool cleaning chemicals. 316 stainless steel is more resistant to corrosion due to the presence of the alloy molybdenum, which provides resistance to heat, salt, and other chemicals – giving 316 stainless steel the moniker of “marine grade”. However, neither grade is immune, so bare stainless must be cleaned regularly and especially when exposed to corrosive chemicals.

Another instance of rust formation is when normal steel is exposed to a stainless steel product surface. An example of this occurrence is when steel wool is used to clean a stainless steel tool. The tiny steel particles on the surface of the stainless steel can cause the surface to fall below a 12% chromium concentration level, and at least a 12% concentration is crucial to protect the stainless steel from rust. If the stainless steel begins to rust in this environment, cleaning the rust and thoroughly cleaning the surface with a solvent to remove steel particles should prevent further oxidation.

Rusting can also occur when stainless steel is exposed to extremely high temperatures, such as in the 750-1,550 degrees Fahrenheit range. Typically, this degradation occurs due to the heating and cooling of the stainless when it is being welded. A process called “sensitization” occurs, in which carbides form when carbon and chromium bond together in the stainless steel. The carbides cause the stainless steel to become deficient of chromium, allowing rust to occur.

How to Prevent Stainless Steel from Rusting and Further Corrosion

The most effective way to prevent stainless steel from rusting is to powder coat the surface. Powder coating involves depositing a dry colored powder onto the stainless steel using electrostatic charges. When the surface is heated, the powder coating cures to a hard finish, thus fully coating the bare stainless steel in an attractive and protective layer.

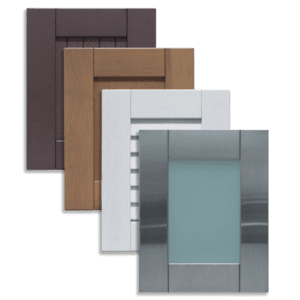

We offer a rich palette of powder coat finishes in many colors and wood grain finishes. Over 85% of the kitchens that have been manufactured in our Connecticut factory are powder coated. We have seen virtually no examples of rust or degradation on our powder coated cabinets in the 20 years have we have been manufacturing our kitchens.

Ready to design your stainless steel outdoor kitchen?

[1] Source: www.polymersolutions.com/blog/why-does-stainless-steel-rust/